Custom Plastic Extruder cuts downtime 71% with Dyna-Purge® D2 – “10 hours of value back to our company.”

Situation

PBS Plastics of Barrington, New Hampshire has over 30 years of specialized experience in precision custom plastic extrusions. The company produces custom plastic profiles, plastic tubing, and pipes in a variety of materials for a wide range of applications. For a specific project, PBS had been using Nylon 66 and they would typically run the job for multiple shifts. Two times during the run, they had to shut down to clean the screw and barrel, using regrind and resin to purge. The result was nearly 14 hours of downtime and a costly delay.

Solution

On the recommendation of a representative, PBS Plastics began using Dyna-Purge® D2 engineered purging compound before removing the screw. Dyna-Purge D2’s innovative scrubbing formulation made cleaning the screw and barrel easier than ever, cutting 10 hours off of the previous down time – a 71% time savings. “That is 10 hours of additional value given back to our company,” reports Craig Croteau, Operations Manager at PBS Plastics. “Employees can use the time we save on other jobs within our facility for greater productivity.”

Results

- Using Dyna-Purge D2 reduced overall downtime by 71% – giving back 10 hours of productive time to the company.

- Dyna-Purge D2 is more effective than regrind and resin for purging, resulting in faster, easier cleaning.

- Dyna-Purge D2 thoroughly cleans and removes material from the screw and barrel as well as the tool or die.

PBS Plastics has reduced downtime on a specific extrusion job by 10 hours using Dyna-Purge D2.

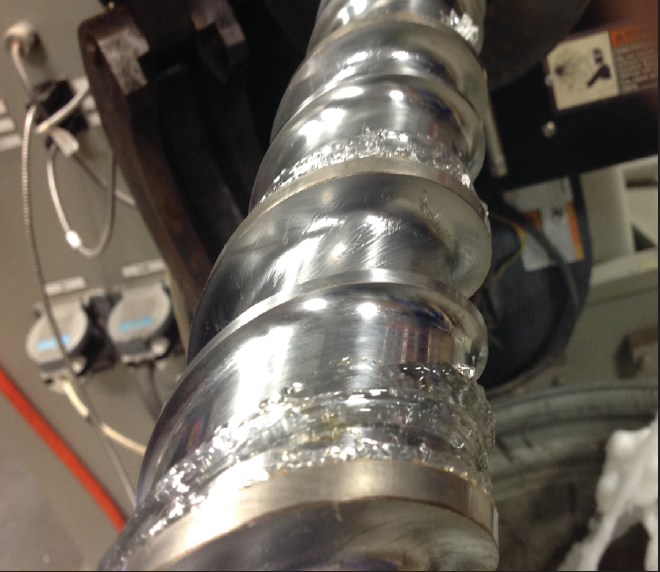

Dyna-Purge D2 cleans and removes material from the screw and barrel to make cleaning faster than ever.

Download PDF Version

Download PDF Version