Dyna-Purge Case Studies

Click on the case studies below to see how customers are using Dyna-Purge to improve their business.

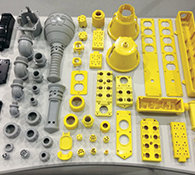

Custom Injection Molder reduces scrapped parts tenfold with Dyna-Purge® D2 – “the formula is in a different league.”

Custom Molder saves time and money switching to Dyna-Purge D2 – “a great product that meets all of our molding needs.”

Dyna-Purge Products

Learn more about

the products we offer.

Dyna-Purge in the News

Check out our most recent article

in Plastics Technology

Free Sample

Choose any product and have it

shipped today!